How is Beer Made?

Beer is one of the most popular drinks around the world. A true beer lover therefore feels blessed by the many different varieties he or she can choose from. From light to dark and from low to high alcohol content. The number of different beers to choose from is almost uncountable. For almost everyone, you can find a beer that is completely to your taste.

But where do the different flavours actually come from? How are such beers brewed? And how come different beers have different flavours? Few people know the answers to these questions. Hence, we hereby take a closer look at the process around brewing beer. We would like to take you through the entire process of which a drinkable beer is ultimately the result. That starts, of course, with the ingredients.

How does beer brewing work?

We like to take you through the whole process that a drinkable beer is ultimately the result of. It starts, of course, with the ingredients.

The ingredients of beer

Let's start at the beginning, the ingredients. Just like any other form of drink or food, the total consists of a few different ingredients. In this case, we are talking about the following 4 ingredients of beer:

The ingredient with the largest share in the final beer product is water. In fact, more than 90% of beer is water. The minerals in the water used are essential here. This is because the amount, composition and ratio of minerals says something about how the beer will taste.

When water is very soft and low in minerals, it can be used well for a smooth and clean beer. A Pilsener is a good example of this. On the other hand, water that contains a lot of minerals is better suited for hop bitter beer. The well-known Pale Ales are another example of this.

So a brewer pays close attention to the proportion of minerals in the water he or she uses when brewing a beer. This can have a considerable influence on the end result.

Another basic component of beer is malt. This involves grain that is first germinated and then dried. Special malting barleyis required in the process, as normal barley cannot be used in brewing beer. The type of malt you use is then of decisive importance in terms of the smell, colour, taste and head of the beer. This is what malt is responsible for. So it is very important to think beforehand about what kind of beer you want to brew and what kind of malt you need.

In terms of malt, you can choose between the following types of grain:

- Barley: This is the most popular option. This is mainly due to the favourable ratio of starch to protein in this type of grain. Moreover, it contains valuable enzymes for in the brewing process and barley is firm enough for a later phase of brewing.

- Wheat: If you use wheat during the brewing process, your beer will end up with a slightly cloudier look and a slightly larger head. This is due to the large amount of protein in this type of grain.

- Oats: Provides the flavour of oatmeal. Recognisable by the fuller and more velvety mouthfeel of the beer.

- Rye , on the other hand, gives beer a slightly more spicy flavour. In the distance, it reminds some palates of rye bread.

- Other cereals: There are also other types of grain, all with specific properties. Examples are maize, spelt, emmer and rice.

With hops, we have arrived at beer's most precious ingredient. The advantage, then, is that as a brewer you don't have to use too much of it. Thanks to hops, a beer gets its bitter characteristics and also imparts a scent. Moreover, hops are very valuable when it comes to shelf life. In fact, hops have a preservative effect. It ensures that bacteria are killed. Also in terms of hops, you have a wide range of different options to brew your beer with.

They can be roughly divided into three main categories:

- Bitter hops: As the name suggests, bitter hops give beer a bitter taste. This is the case thanks to the alpha acids that are converted into bitterness during the building process.

- Aroma hops: Aroma hops contain certain oils, which give off a fruity or floral aroma. So with this type of hop, the focus is more on the aroma, or fragrance.

- Dual-purpose hops: Dual-purpose hops contain the aforementioned alpha acids as well as aroma hops.

The fourth and final main ingredient in beer is yeast. A living organism, of which there are as many as hundreds of different species. For the brewing process, isolated yeasts are preferred. This means that all yeast cells are completely identical. Again, in terms of yeast, there are different types. Briefly, you have top yeast, bottom yeast and spontaneous yeast.

The different processes of brewing beer

Now that we have gone through what the necessary ingredients in beer brewing are, it is time for the processes themselves. Because after collecting the ingredients, of course, you are far from finished. The brewing process can be divided into a number of different steps. We will briefly go through these steps to give you a better idea of what happens behind the scenes when producing a beer.

Making different types of beer

How do we make all the different types?

What not many people are aware of, and what we already briefly touched on above, is that in terms of fermentation, there are three different options that produce three very different results. They are therefore seen as three different forms of beer making. We are talking about:

In low fermentation, the yeast sinks completely to the bottom. To achieve this, the yeast species Saccharomyces carisbergensis is used . This form of fermentation takes relatively longer and takes place at temperatures of 4 to 12 degrees Celsius. It is mainly a popular method because there is little risk of bacterial contamination. Because of this, many large brewers often choose this method. It is safer. An example of a well-known beer brewed by low fermentation is Pilsener.

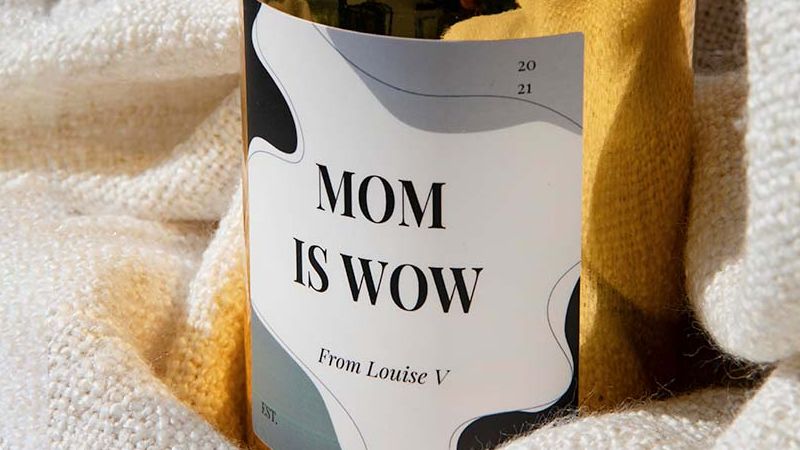

In the case of high-fermentation, the yeast actually stays at the top. The yeast species Saccharomyces cerevisiae is used at temperatures of 15 to 25 degrees Celsius. Thanks to this higher temperature, this form of yeast is also more susceptible to bacteria. This makes the fermentation process more difficult to control. Since the risk level here is higher, smaller quantities are often produced at once. In turn, an advantage is that a lot of esters are produced as aby-product of the yeast. This gives a unique flavour to the beer, which attracts many brewers. Because when it does succeed, the beer obtained is of a special quality. An example of beers brewed by high fermentation are our beers, namely these from makeyour.com

The main difference between spontaneous fermentation and the two aforementioned forms is that there is no control over the type of yeast used. The wort obtained is exposed to the open air so that wild yeast cells start fermentation. This method ultimately results in different flavours, which would not have remained with other methods of fermentation. It creates a more unexpected flavour, so to speak .

Lots of information, of course! Who can keep up? Much more important, of course, is the tasting itself. Because that remains the most important thing of all: a fresh and tasty beer.

All our beers are traditionally brewed. We work together with Brewery Van Steenberge from Ertvelde, a brewery known for its quirky beers such as Augustijns, Gulden Draak and Baptist.

The beers are brewed according to tradition and with great craftsmanship. The brewery also values welfare and the environment and only uses ingredients that meet the highest quality standards. Love for the craft is certainly not lacking here. Design your own bottle, order your beer online and taste it yourself!

May be of interest to you

Why choose makeyour.com?

With more than 100,000 satisfied customers, we are known for unique gifts for unique gift moments

At makeyour.com you can personalise your gifts